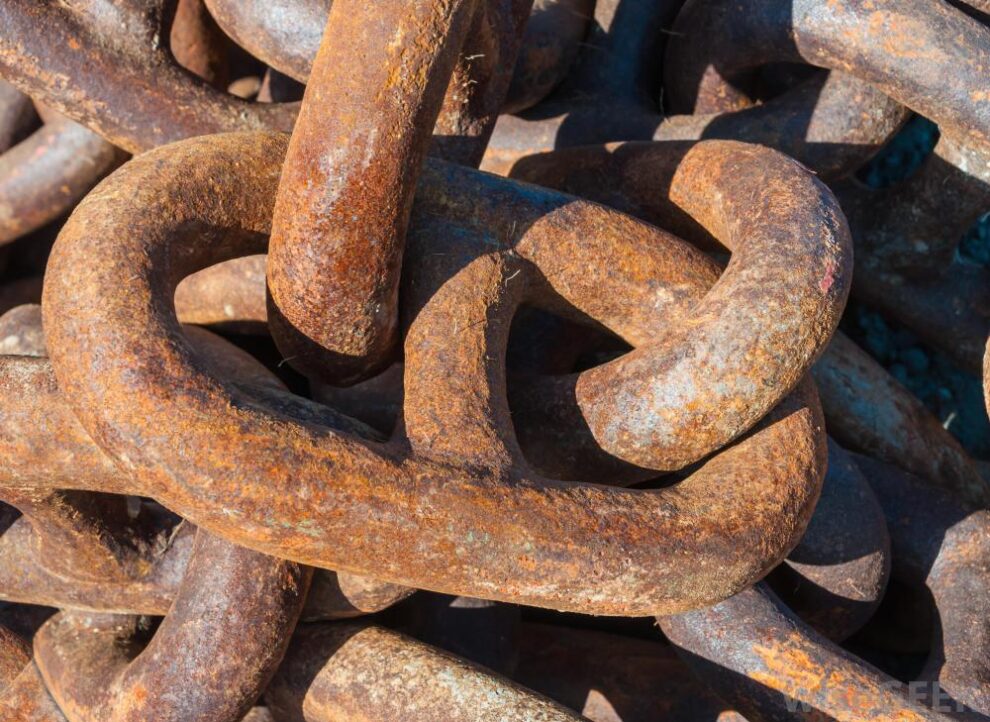

If you’re in a business where you need to use various equipment pieces, you need to be aware of corrosion and the damage it can do. With most or all of the atoms on a metal surface subjected to oxidization, general corrosion occurs, and it can damage the entire mechanism.

You should know that most metals oxidize relatively easily. That means they lose their electrons to oxygen, as well as other substances that are in the water or air. As oxygen reduction takes place, which is to say that it gains electrons, it forms an oxide that covers the metal.

Let’s talk a bit about why that makes such a big difference if you rely on various equipment pieces in your business model.

Equipment Malfunctions

If you know about corrosion damage, you know that it can mess up equipment pretty badly in what sometimes seems like a remarkably short amount of time. What you have is essentially a chemical change that the elements are inducing.

If you have complex machinery, such as on a factory floor, on a dock, in a lighthouse, or many other places, you need to watch for corrosion on surfaces. You might think that corrosion isn’t that big of a deal until you see how the damaged devices no longer pass electrical and data impulses the way that they should.

Overheating Concerns

If you decide to ignore corrosion, one thing that can happen is that your equipment can overheat. Your machinery probably has electronic and electrical devices embedded in it. These sensitive micro-electrical components are not likely to function correctly if they can’t dissipate heat properly.

The device is going to fail once the corrosion has occurred. It’s just a matter of when. You may be able to get away with using it for days or weeks, but probably you’ll see overheating before much longer than that.

Switchgear and motor starters are perfect examples. You’re dealing with components that need to dissipate heat as they provide resistance. It’s easy to see how a corrosion-caused heat buildup can prevent this from happening.

What Can You Do About It?

The first real way to fight corrosion is to only buy equipment or materials with the right chemical composition. In other words, if you’re going to be working in an area where you know corrosion damage is likely, you should look into what kinds of materials would function well there versus ones that would not.

You might have equipment composed of certain elements that can sit for weeks in one spot, and you’ll never see any real corrosion damage. You might have another piece sitting next to it, and because of its composition, you might have irreparably damaged it within 24 hours or even less.

What Can You Do if You Have Impacted Equipment?

If your business relies on equipment that corrosion damaged, you basically have two choices. The first thing you can do is scrap it and consider what happened to be a learning experience. In the future, you’ll know to buy equipment made using different materials.

The other thing you might do is to contact an equipment refurbishment or restoration company. They might replace individual components so that you can continue using the equipment, or they might be able to scour off the corrosion in some instances.

If you do want to try to save the equipment, you’ll need to bring in a professional since you won’t know on your own whether you can save any element of what you have. If you can save it, you should probably try to do so since this is likely the much cheaper option than buying all-new equipment and starting from scratch.

You might not have the money to buy all-new equipment, even if you wanted to opt for this solution.

Stop the Problem Before It Starts

Aside from getting the right equipment next time, you can also bring in a restoration company so they can look over your entire operation and point out any areas where you’re likely to have problems in the future.

These companies usually employ engineers and individuals with unique restoration backgrounds. They can show you how to have business continuity so you won’t need to worry about these issues down the line.

Ignoring corrosion is one of the worst things you can do. By doing so, you endanger your workers’ lives, and you virtually guarantee a service interruption. If that happens, you’ll get a poor reputation within your industry.

Add Comment